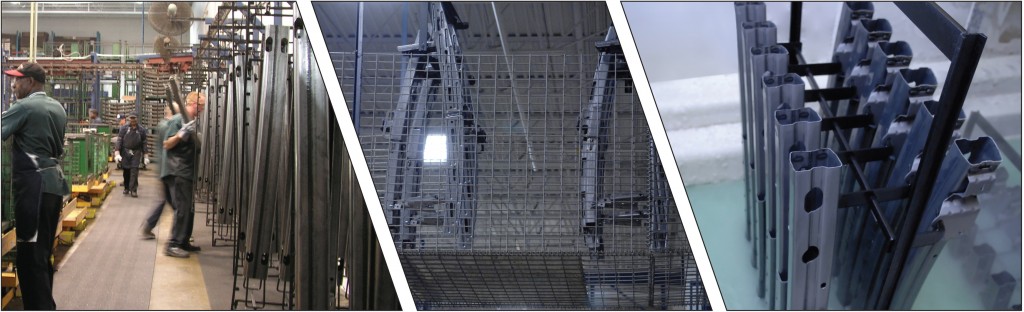

Electro-deposition coating adds a strong, affordable and superior quality finish to your product. Shape is home to one of the largest e-coat lines in North America. Designed to accommodate large parts (up to 18′ x 36′ x 84′) at high volumes, this automotive Class A surface quality line is state-of-the-art.

Shape’s e-coat process provides a uniform and controllable coating thickness that is startling cost effective and environmentally friendly. The e-coat process ensures complete part coverage and consistent quality by dipping your parts in a series of baths and taking advantage of electrical bonds. The result is a durable, corrosion-resistant finish that is ready for final assembly.

- Uniform, controllable coating thickness

- Competitive piece price

- Excellent corrosion resistance

- Complete part coverage, inside and out

- Consistent quality

- Environmentally friendly process (extremely low V.O.C.s)

- Aesthetic or protective top coats can be applied over the e-coat

POWDER COAT FINISHING

Powder coat finishes further enhances Shape’s manufacturing capabilities and allows more aspects of your product to remain under our strict quality standards. Shape’s custom powder coat line was designed to accommodate large parts, and has a transfer point from the current e-coat line to allow for a smooth transition between finishing operations.

At its core, the powder coating process provides additional protection and corrosion resistance. Instead of applying paint in liquid form, powder coating applies paint as an electrically charged cloud of particles that are attracted to the grounded part. After a part is coated, it passes into an oven where the powder is melted into a liquid and then hardened into a finished coating, giving you an extraordinary finish that matches Shape’s superior manufacturing processes.

- Steel and plastics powder coating capabilities

- Enhanced appearance

- Competitive piece price

- Proven as economical (overspray can be recycled)

- Excellent corrosion resistance

- Durable; resists chipping, scratching, and fading

- When combined with e-coat, provides protection against weathering, road salt and rusting

- Environmentally friendly process (extremely low V.O.C.s, uses no solvents)